More powerful engines, modern exhaust gas technologies and innovative materials used in the construction of passenger cars and commercial vehicles call for greater use of insulation for exhaust systems. Heat protection shields are an excellent solution and perform two different functions.

Depending on the object to be protected and the heat source in question, heat protection shields can be applied in two areas:

To manufacture its heat protection shields, HKO uses needle and stitch-bonded needle mats that are also available in sandwich constructions incorporating aluminium or stainless steel foils as well as self-adhesive foils or fabrics. HKO materials offer

and are guaranteed non-toxic.

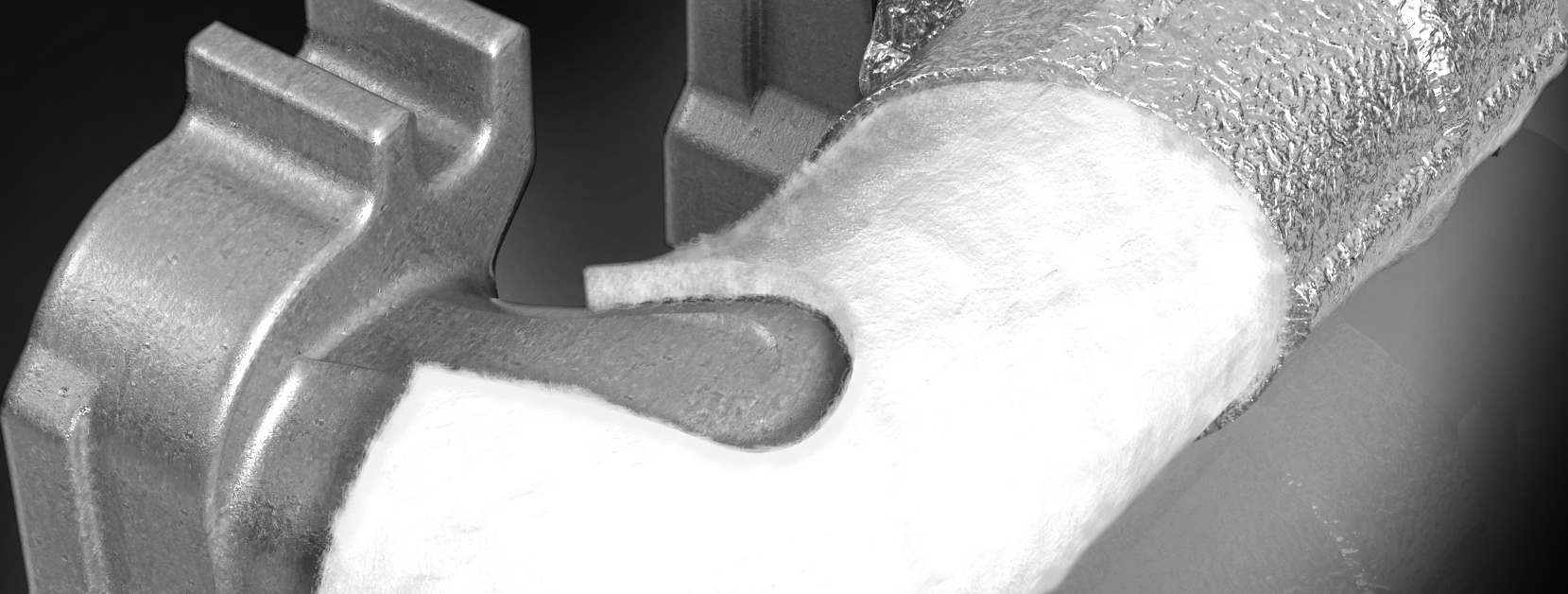

The exhaust manifold links the engine block and the exhaust system. It comes directly into contact with exhaust gases exiting the engine at temperatures of up to 1000 °C. The manifold is constructed of grey cast iron or stainless steel. The shape varies from a simple collector to complex double-wall designs. In addition to air-gap insulated manifolds, there are also manifolds that are produced using insulation materials. When it comes to insulating manifolds, HKO offers 2D stamped parts and 3D moulded parts made of needle mats and stitch-bonded needle mats for various temperature ranges.

These are entirely non-toxic and are used to reduce temperature loss and to protect adjacent components against heat. The insulation materials from the HKO Heat Protection Group also offer

Protection for the inner core

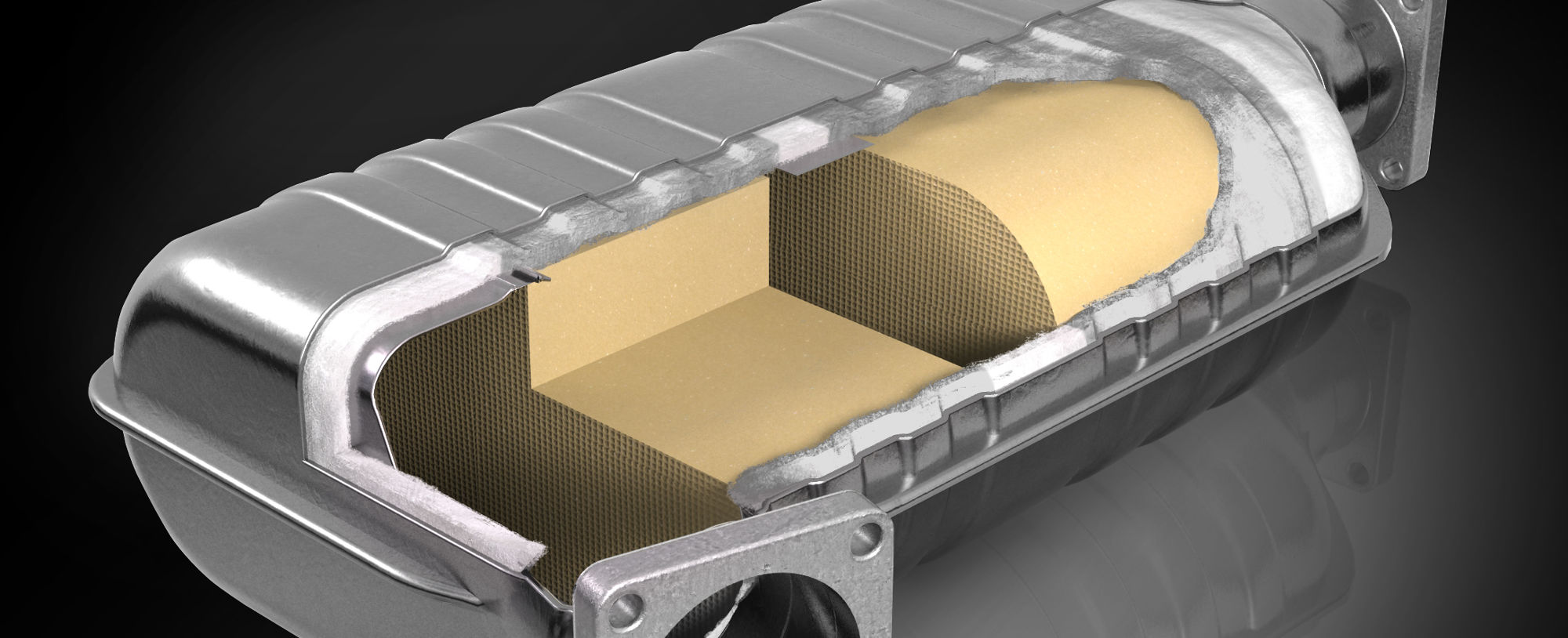

Due to the high gas temperature, the inlets and outlets on the catalytic converter must be insulated. Based on experience, temperatures in this case range from 800 – 1000 °C. The same problem also applies to diesel particle filters, although temperatures are not quite as high and are approximately 100 °C lower than those of a typical catalytic converter.

High temperatures and strong pulsation levels call for the use of HKO materials for absorptive as well as baffle silencers. In this case, also the acoustic properties of mineral-fibre products are very important.

For insulating catalytic converters, diesel particle filters and silencers, the HKO Heat Protection Group offers 2D stamped parts and 3D tubular sleeves made of needle and stitch-bonded needle mats for various temperature ranges.

Turbo solution in 3D

The market share of high-performance engines, both diesel and petrol, that feature state-of-the-art turbochargers is increasing. In these applications, the turbocharger body can easily reach temperatures of over 800 °C.

Turbochargers must be insulated to prevent them from driving up temperatures in the engine compartment and to protect surrounding components. When it comes to insulating turbochargers, the HKO Heat Protection Group has developed special 3D moulded parts that offer

and are non-toxic.

Tailor-made solutions

The use of modern technologies in vehicle construction involving sensitive electronic components or innovative auxiliary drive units makes efficient shielding indispensable. Temperature increases in the engine compartment mean that

must be protected against heat. However, there are also applications that require protection against the cold. For all such applications, the HKO Heat Protection Group offers pre-fabricated solutions. These can be heat shields or sleeves as well as hose sheaths, which are available with Velcro closures, snap fasteners or stitched versions.